PRODUCT LINES

Metal Treatment Chemicals

Chromating / Phosphating

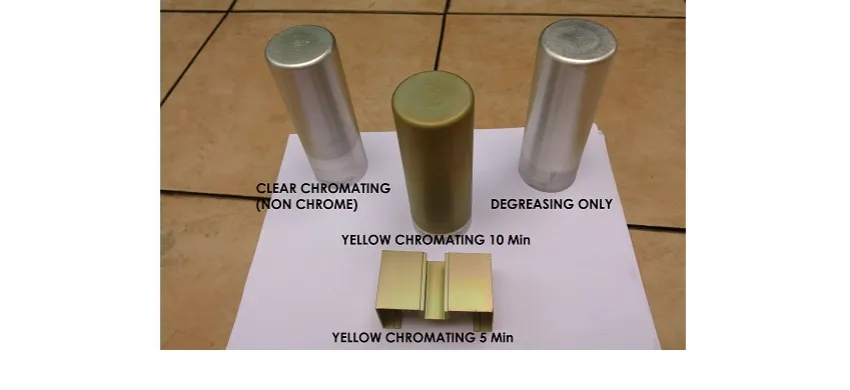

Chromating (chromate conversion coating) is a type of conversion coating mostly used to passivate aluminum, although it can be used for other metals such as steel, zinc, cadmium, copper, silver, magnesium, and tin alloys. It is primarily used as a corrosion inhibitor, primer, decorative finish, or to retain electrical conductivity. The process is named after the chromate found in chromic acid, also known as hexavalent chromium, the chemical most widely used in the immersion bath process whereby the coating is applied.

Phosphate coatings are used on steel parts for corrosion resistance, lubricity, or as a foundation for subsequent coatings or painting. The main types of phosphate coatings are manganese, iron and zinc. Manganese phosphates are used both for corrosion resistance and lubricity and are applied only by immersion. Iron phosphates are typically used as a base for further coatings or painting and are applied by immersion or by spraying. Zinc phosphates are used for corrosion resistance (phosphate and oil), a lubricant base layer, and as a paint/coating base and can also be applied by immersion or spraying

We have a special formulated chemicals of Chromating and Phosphating for many metal industry requirements, such as automotive, furniture, panel industries etc.

Phosphate coatings are used on steel parts for corrosion resistance, lubricity, or as a foundation for subsequent coatings or painting. The main types of phosphate coatings are manganese, iron and zinc. Manganese phosphates are used both for corrosion resistance and lubricity and are applied only by immersion. Iron phosphates are typically used as a base for further coatings or painting and are applied by immersion or by spraying. Zinc phosphates are used for corrosion resistance (phosphate and oil), a lubricant base layer, and as a paint/coating base and can also be applied by immersion or spraying

We have a special formulated chemicals of Chromating and Phosphating for many metal industry requirements, such as automotive, furniture, panel industries etc.